About Us

Business and Company Profile

Manufacturing that supports a sustainable future:

Our products and services serve the infrastructure of society.

Based on 100 years of experience in copper processing, a wide variety of metalworking products are produced to full order

Since its foundation in 1923, KYOWA Electrical Inc. has continued to provide high-precision products as a professional copper processing company.

Copper is an energy-efficient metal with excellent thermal conductivity. Therefore, our company has a wealth of experience in the production of metal components, particularly in relation to electrical infrastructure equipment.

At the same time, we are not limited to copper, but have also accumulated processing technology and experience in a variety of metals, including aluminum, which is ideal for weight reduction, and can offer a wide range of proposals for product development issues.

Business

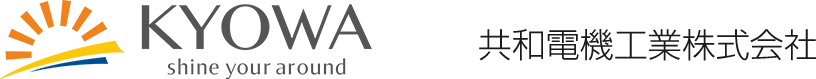

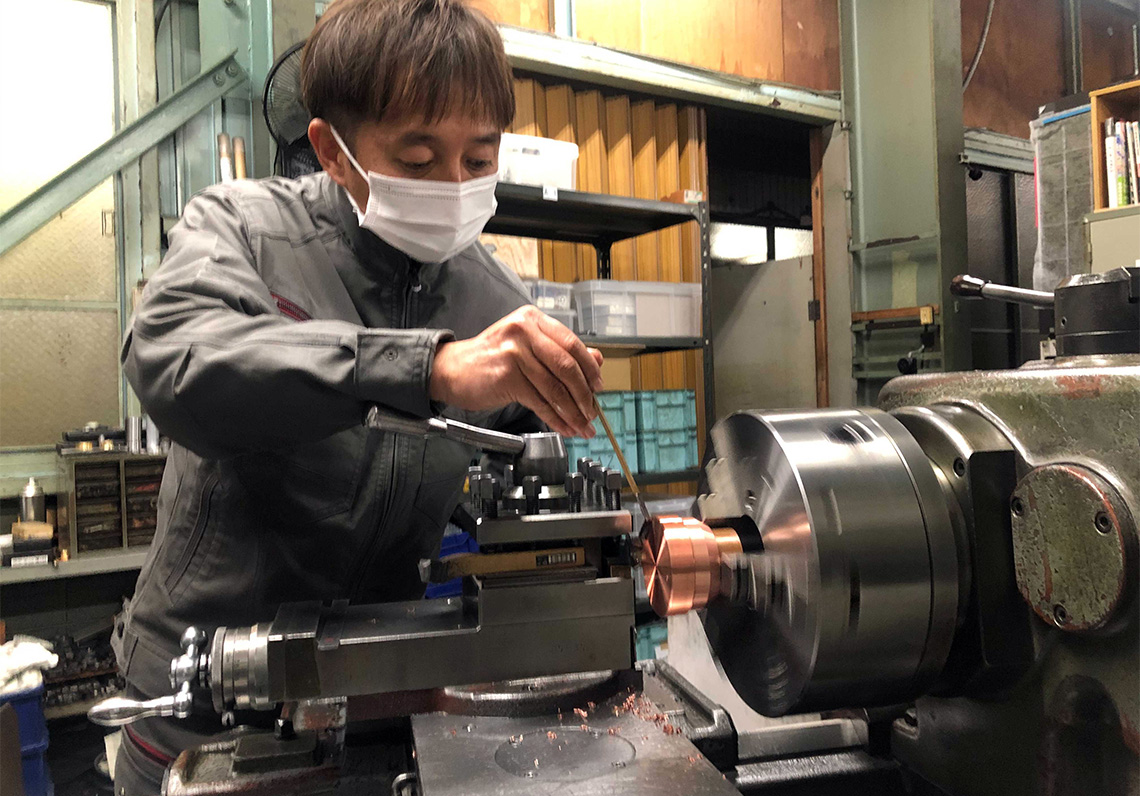

We provide integrated services from component fabrication to assembly and quality inspection, and respond to a wide range of needs from prototype production to mass production.

We primarily deal with metalworking, assembly and cable processing.

In metalworking, the company undertakes the manufacture of various products, as well as secondary processes such as plating and brazing.

In assembly, we manufacture tap changers for large transformers, coppercoils, and copper strips using copper wire.

In cable processing, we can crimp terminals up to 120sq and process plugconnections up to 10 cores.

We also focus on our inspection system. We have introduced a three-dimensional measuring instrument and conductinspections tailored to our customers’ needs to provide them with peace of mind and safety.

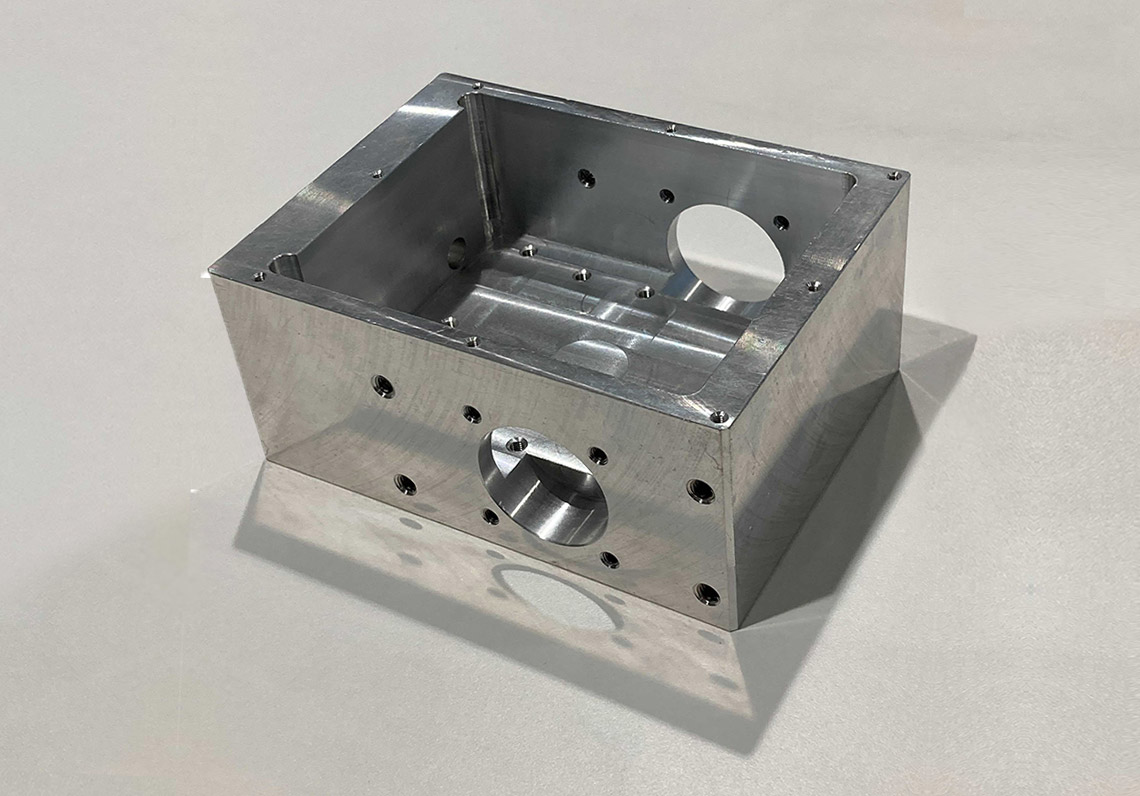

Machining center processing

Machining center processing Lathe machining

Lathe machining Press working

Press working Cable processing

Cable processing Assembly

Assembly Quality check

Quality checkProducts

We introduce here by category the metalworking products that we have manufactured many times. Within the scope of what our processing equipment can handle, we can manufacture products according to customer requirements in terms of size, shape, material, etc.

All product images are an example.

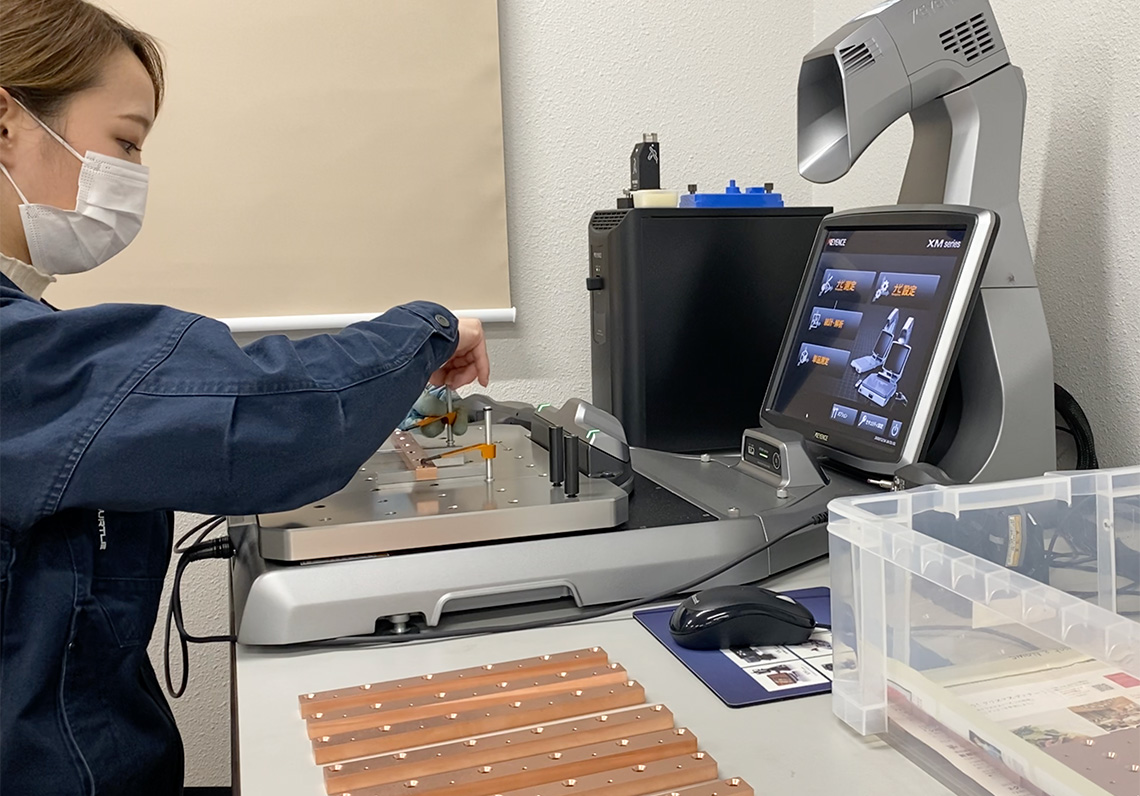

Cutting products

We manufacture machined products of various metals including copper, aluminum, and iron.

Examples of production: Electricity parts (transformers), semiconductor manufacturing equipment parts, welding machine parts, railroad parts, medical related parts, construction related parts, etc.

Copper sheet and plate

Flange

Shaft, pin

Block

Ring

Bus bar

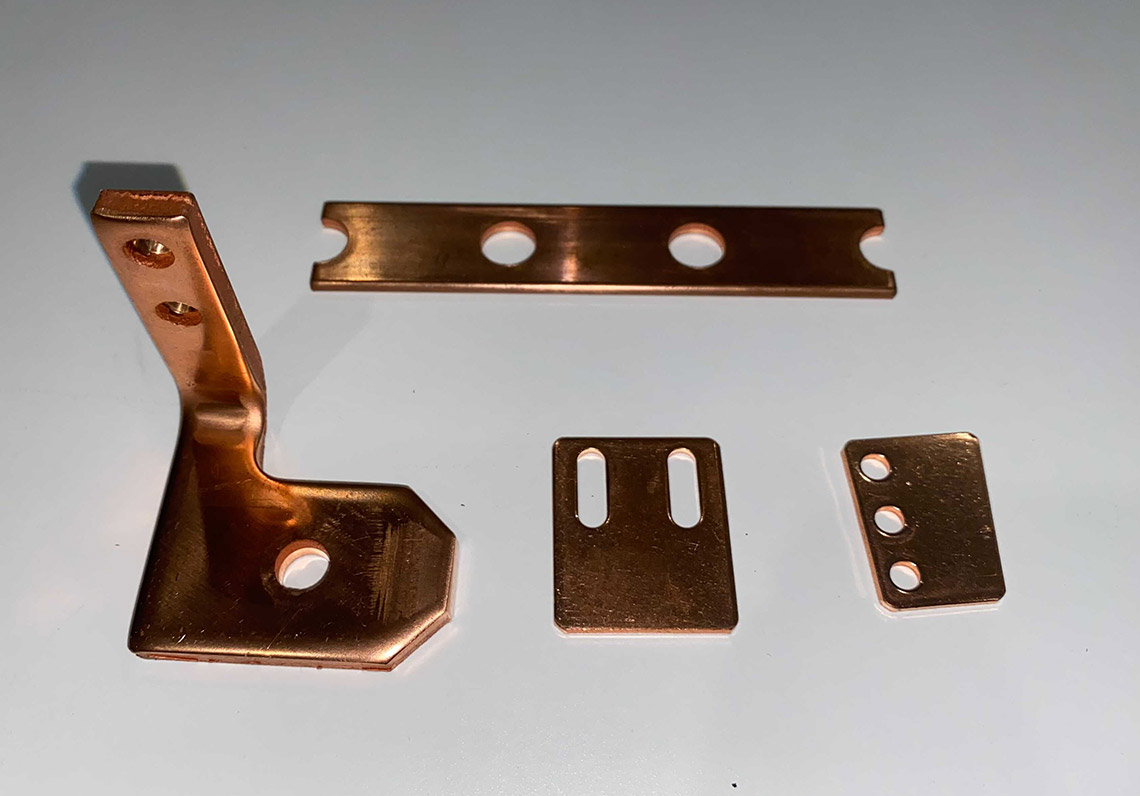

Sheet-metal products

This is a typical example of a sheet metal processed product by a press machine. We can also manufacture products by supplying dies.

We offer VE proposals for die press work to reduce costs upon request.

We can manufacture a wide variety of products in small quantities. We also have experience in prototype production.

Examples of production: electrical power components (transformers), semiconductor manufacturing equipment components, railway components, food plant components, etc.

Bussbar (bending process)

Washer

Copper terminal

Sheet copper

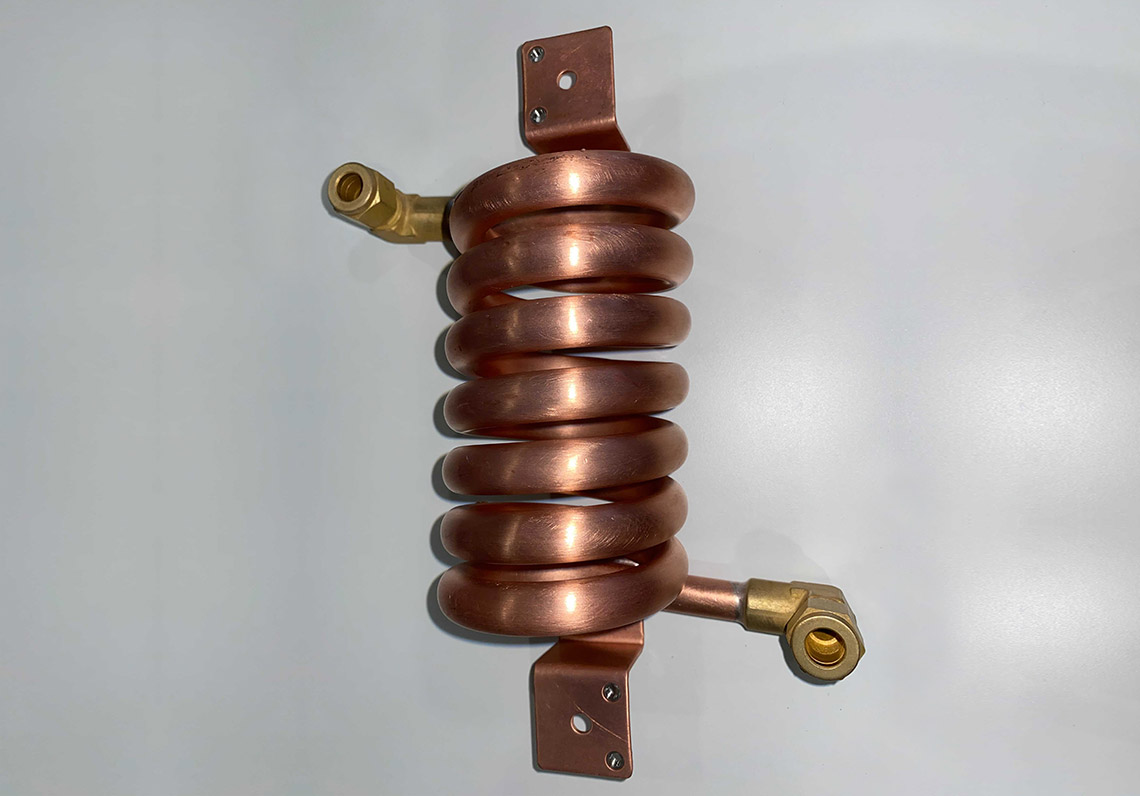

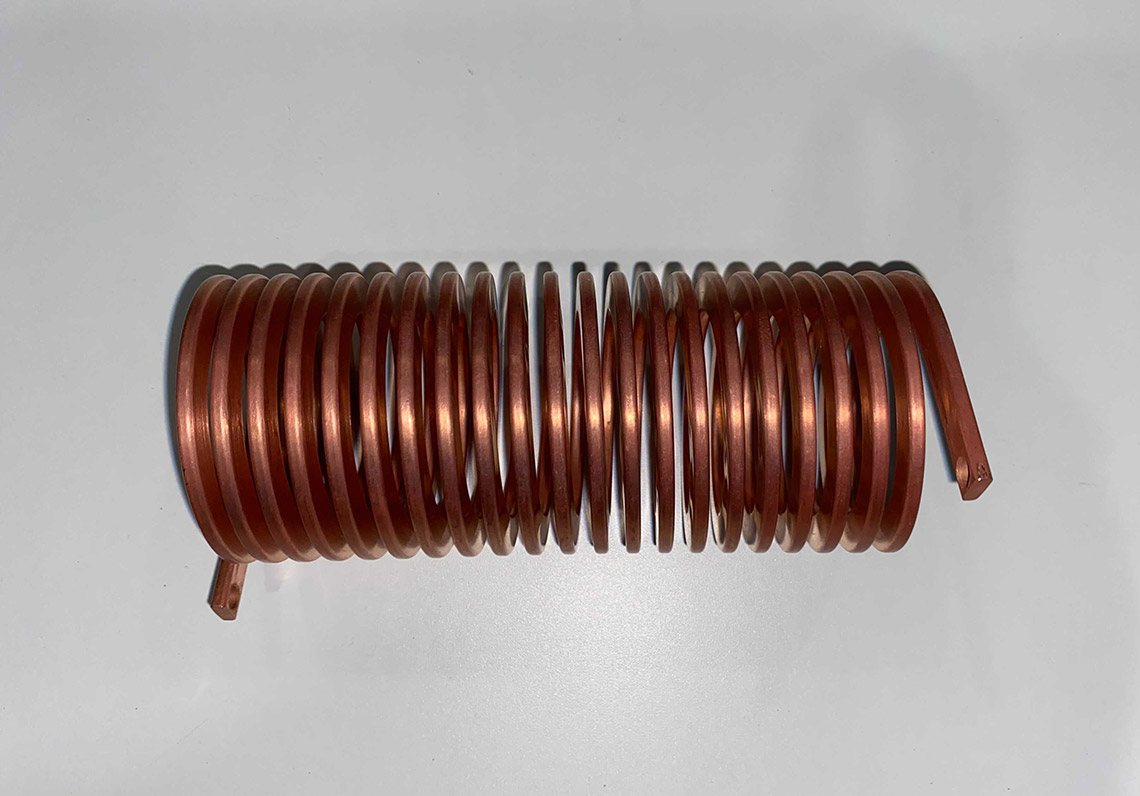

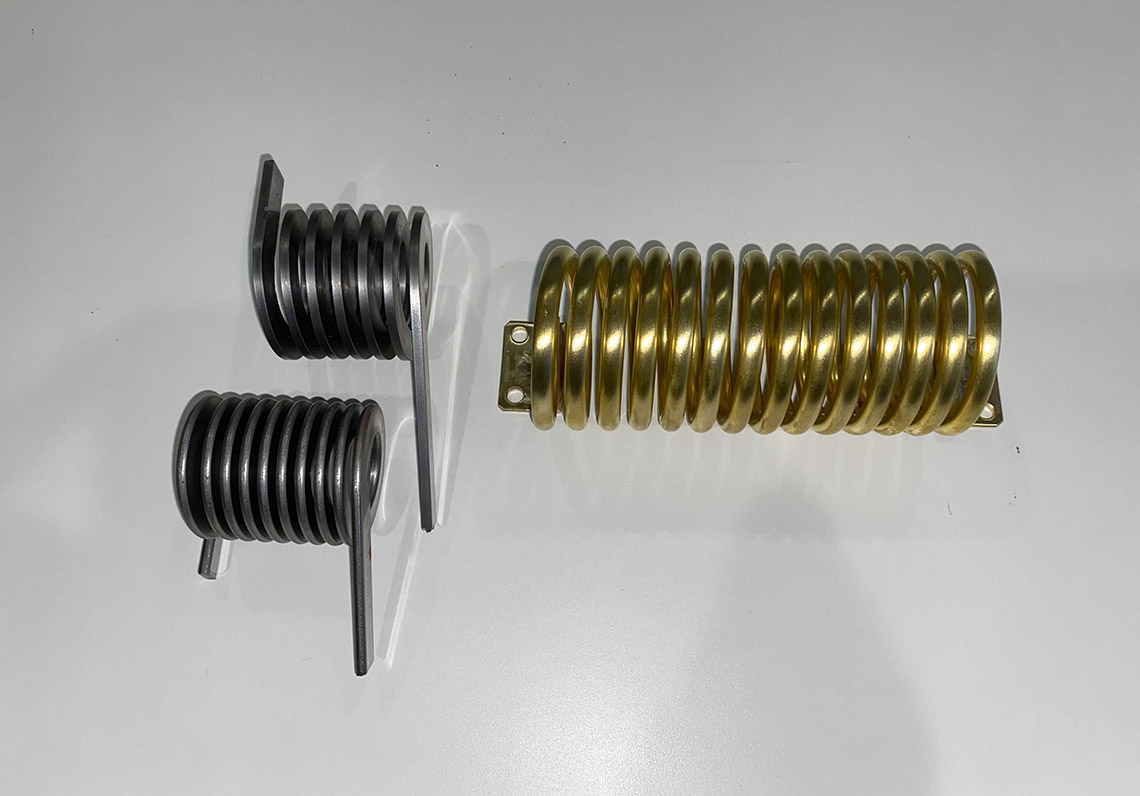

Coil processing products

Mainly manufactures spring coils such as inductor coils and reactor coils. Prototypes are also available. For trial production of inductor coils and reactor coils, we have prepared our standard materials in advance to meet short delivery times.

Examples of production: Semiconductor manufacturing equipment parts, mesh processing equipment jigs, etc. The materials used are mainly copper, but also brass, iron and aluminum.

Copper pipe coil

Copper flat wire coil

Enameled wire Coil

Iron coil, brass coil

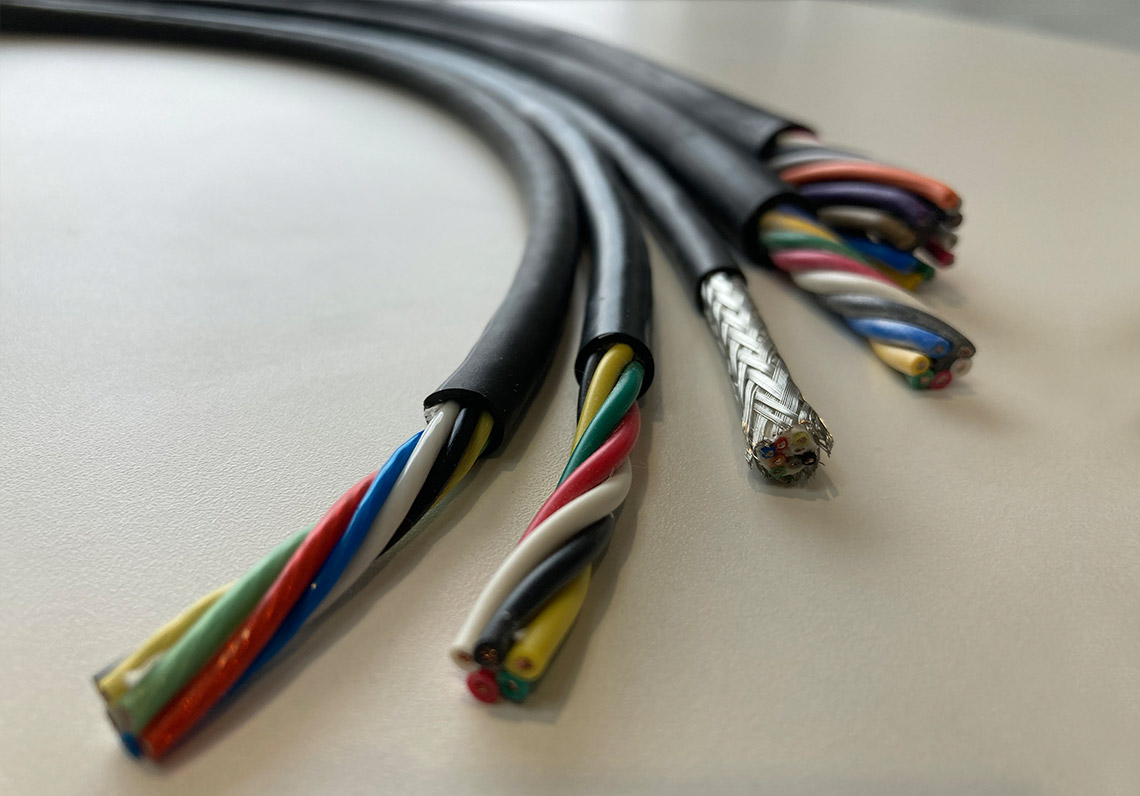

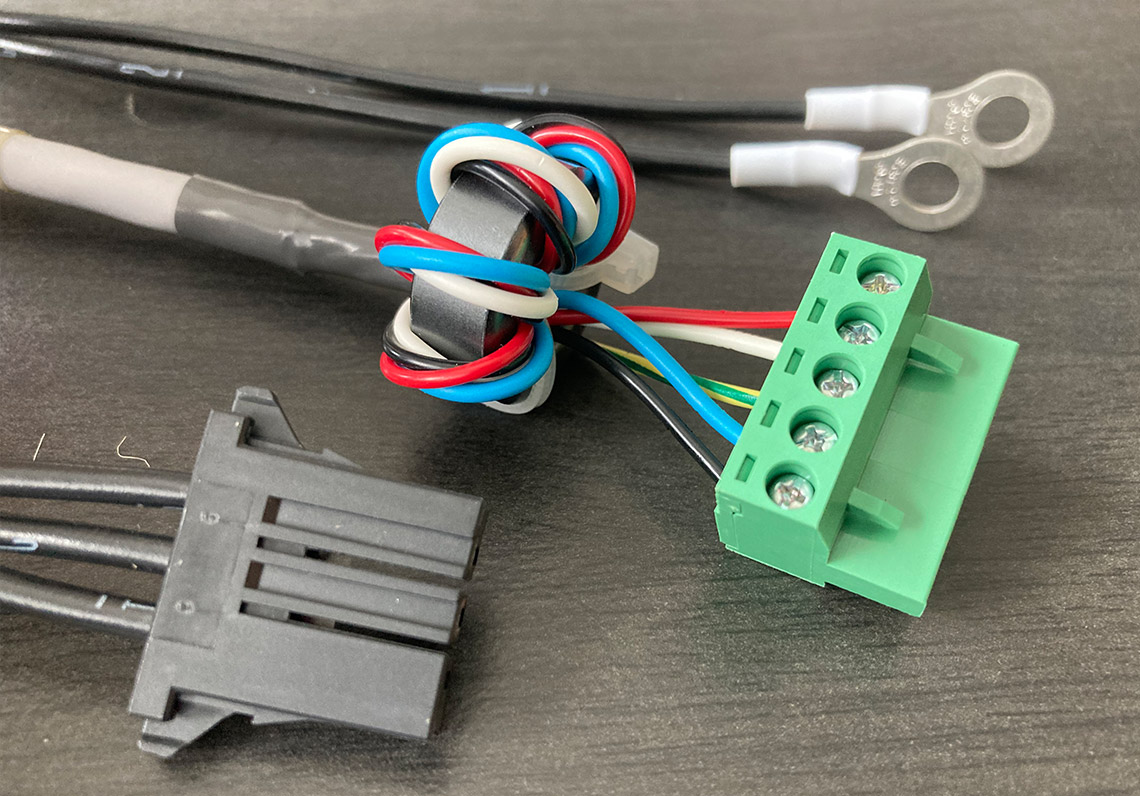

Cable processing products

We provide a wide variety of cables (thin to thick) including control cables and cabtyre cables, as well as processed and assembled gas hoses.

In-house manufacturing in Japan ensures high quality and flexibility in custom-made products. Please feel free to contact us for prototype production, shortened delivery times, and VE proposals.

Crimping: Crimping terminals (up to 325 sq. min.), crimp processing of various manufacturers’ contacts.

Soldering: Soldering various connectors, plugs, etc.

Examples of production: Welding machine related cable processing

Control cable

Cabtyre cables for welding

Rubber cabtyre cable (2PNCT)

Vinyl cabtyre cables (VCT/VCTF)

Harness

Gas hoses for welding, cooling hoses, etc.

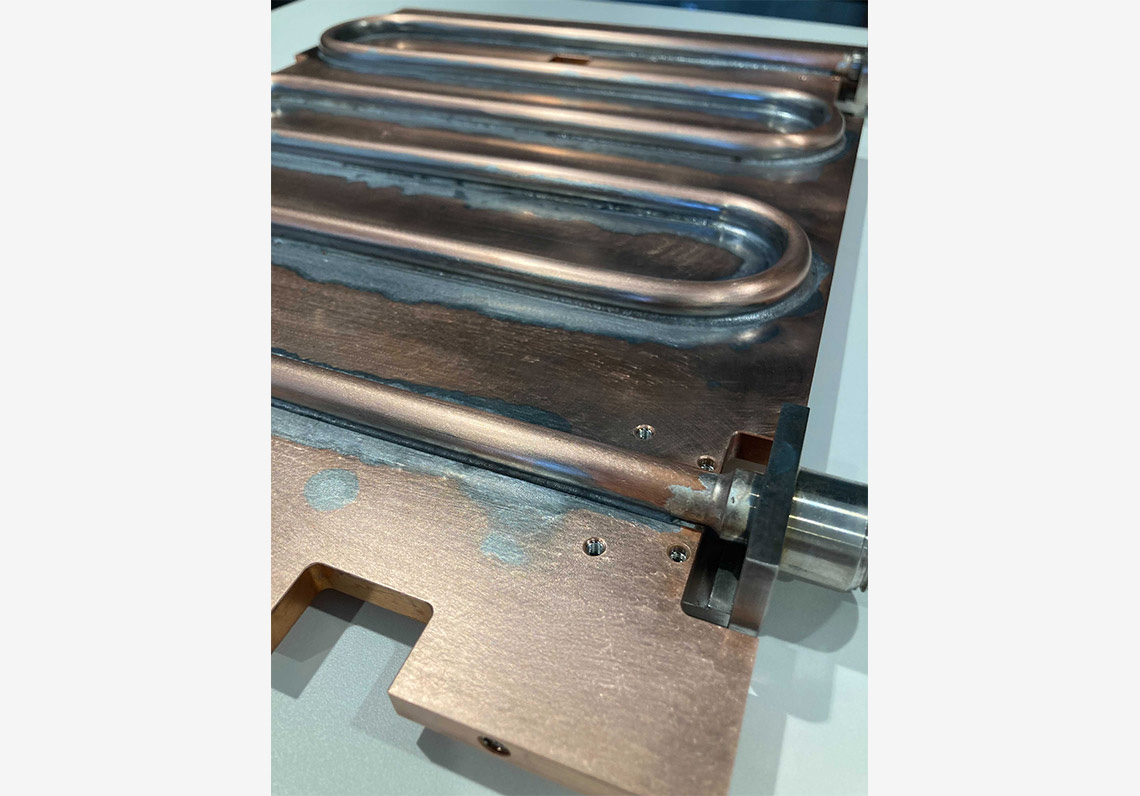

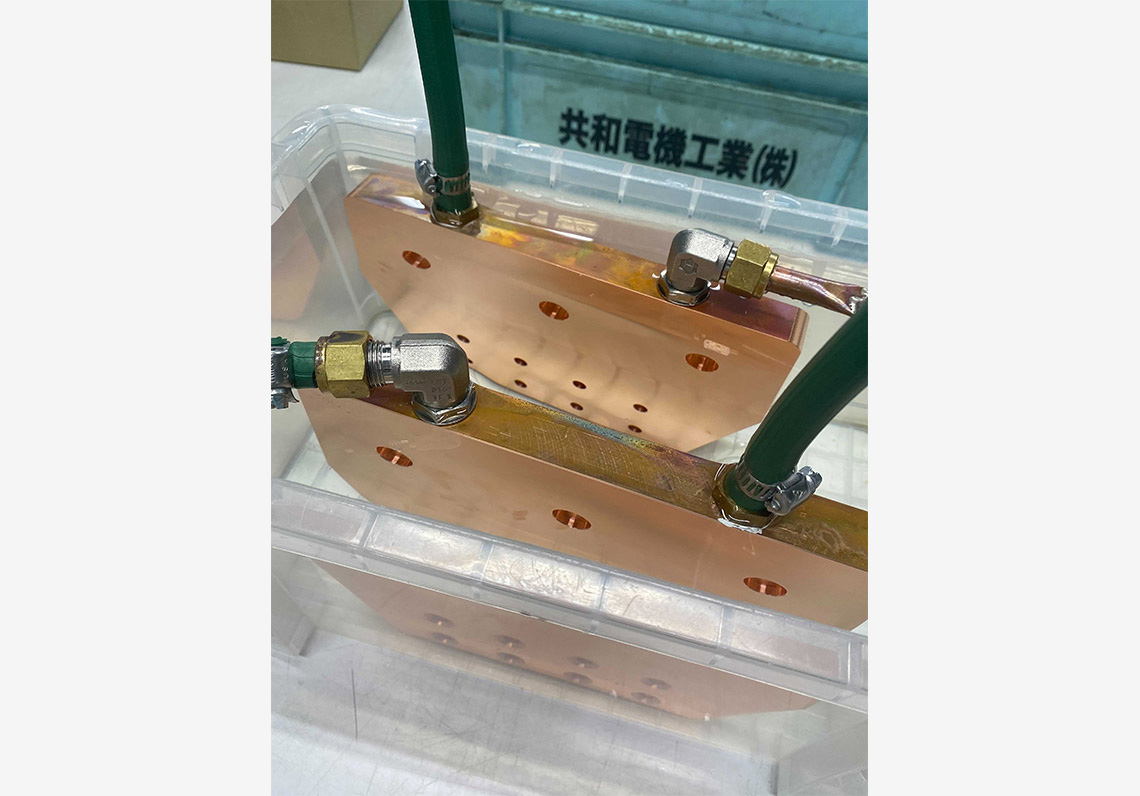

Water-cooled copper plates, cooling copper plates

These are examples of water-cooled copper sheet and cooling copper sheet products that take advantage of the high thermal conductivity efficiency and corrosion resistance that are the characteristics of copper.

In addition to pipetype water-cooled copper sheets, we have experience in manufacturing long-hole through-hole watercooled copper sheets and jacket-type water-cooled copper sheets.

We have achieved uniform and stable cooling performance by making full use of our copper processing, brazing, and plating technologies accumulated over many years.

We can manufacture various types of water-cooled copper plates according to various conditions, such as application, size of heat source, heat load, type of refrigerant, etc., as well as leakage and airtightness inspections. Please feel free to contact us if you have any problems with your design.

Examples of production: Semiconductor manufacturing equipment, etc.

Pipe-type water-cooled copper plate

Water leakage inspection

Compact water-cooled copper sheet (in-house prototype)

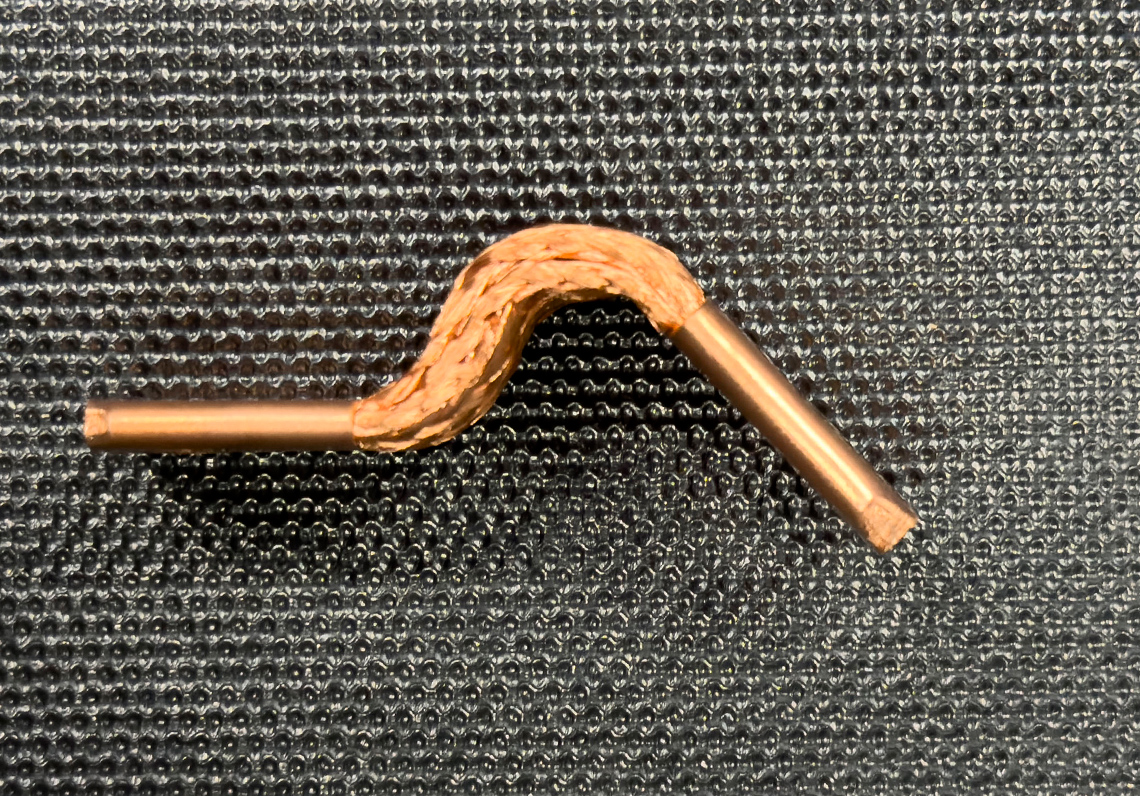

Flexible conductors

We provide “Flexible conductors” for various applications by utilizing our technology and experience cultivated through supporting the development of electric electrical components.

As well as custom-made products, the company also sells standard products, which can be delivered earlier if they are standard.

Examples of production: Electric power components (transformers and switchboards), development parts for automobile manufacturers, experimental parts for university research, etc.

Standard product (standard size)

Custom-made special shape products

Various optional processing

Company overview

| Company name |

KYOWA Electrical Inc.

|

|---|---|

| Location |

Osaka Head Office

2-5-39, Tagawa, Yodogawa-ku, Osaka-shi, Osaka, 532-0027, Japan Phone +81-6-6302-7781 Fax +81-6-6302-3364 Tokyo Sales Office 4-3-20, Toranomon, Minato-ku, Tokyo, 105-0001, Japan Phone +81-3-5404-3437 Fax +81-3-5404-3401 |

| Founding |

December, 1923

|

| Establishment |

April 28, 1956

|

| Capital |

10 million Yen

|

| CEO |

Ryosuke Shimizu

|

| Business line |

– Manufacture of switches for large transformer tap changers

– Semiconductor manufacturing equipment, reactor coil manufacturing for etching. – Metalworking of parts, etc. – Manufacture of cables and torch switches for welding machines – Various interface manufacturing |

| Employee |

32

|

| Factory site |

1,060m2

|

| Factory building |

2,363m2

|

| Accounting period |

End of March

|

Corporate Philosophy

“shine your around”

To create a better society, be the sun and shine around you

Guidelines for Action

- Become the sun yourself and shine around you.

- Live life actively, not passively.

- Make those around you smile a little. Talk to them yourself.

- Life is interpretive power. Look on the bright side.

- Let’s create a better society, a new society.

- What will future society look like? Let’s imagine a new society. Many inputs are needed.

- Heterogenization, not differentiation. Always consider the essence of things.

- Let’s discover challenges by ourselves and be impressed by completing them!

- Even if the processing is difficult at this point, do not give up and think of ways to deal with it.

- The goal should be inspiration. A life with many impressions is a fulfilling life.